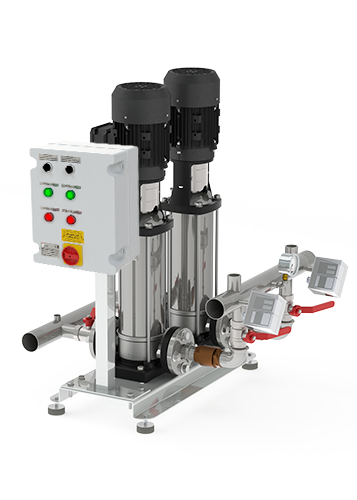

P Version |

|

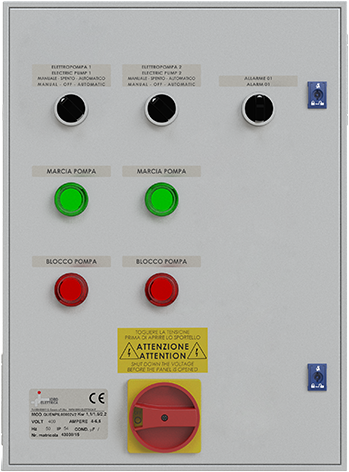

With pressure switch and control from switchboard

|

|

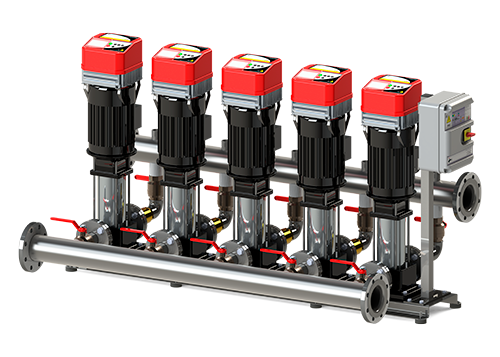

Vertimax

Pressurization units made with 2, 3, 4 or 5 vertical multistage centrifugal pumps

Power supply Single-phase 230V or Three-phase 400V

Pressostatic or Constant Pressure version from Inverter

Download

Description

VERTIMAX pressurization units are systems made with vertical multistage centrifugal pumps coupled with normalized electric motor powered by three-phase voltage. The range includes units from TWO to FIVE pumps. The units are suitable for use within civil, industrial and agricultural installations when high flow rates and heads, continuous operation and limited overall dimensions are required.

The series of stainless steel vertical electric pumps used are of new design; the motor unit and the upper support part, which contains the mechanical seal, are removable without removing the pump body from the installation. The hydraulic parts in contact with the fluid made of stainless steel make it possible to achieve a very high hydraulic efficiency and contain the committed power.

Choice of command type (Version)

Available Versions

EP Version |

|

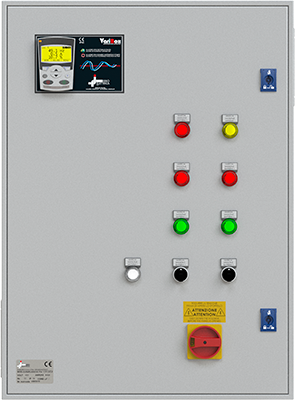

With control from pressure transducer and control from inverter

|

|

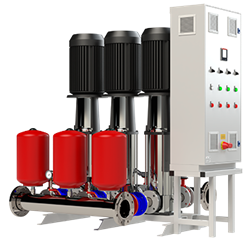

IP Version |

| With control from pressure transducer and switchboard control with inverter complete with emergency pressostatic ciscuit |

|

PV Version |

|

With control from pressure transducer and inverter on board motor (one for each pump)

|

|

LIMITS OF USE:

- Clean liquids, not containing abrasive particles, not chemically aggressive

- Max. temperature of the liquid 90° C

- Maximum temperature of the environment 40° C

In case the units are to be used with osmotized or deionized water, please send detailed technical specifications to our technical department.

COMMON COMPONENTS:

- Folded sheet metal base

- Height adjustable feet for optimal insulation against noise propagation.

- From 2 to 5 three-phase electric pumps with motors at 2900 rpm IE2

- Stainless steel suction manifold

- Stainless steel discharge manifold

- Provision for mounting diaphragm storage tanks.

- Shut-off ball valves, on suction and discharge

- Check valve on the discharge.

- Glycerin bath pressure gauge on the discharge manifold.

P VERSION:

- Control pressure switches (one each pump)

- Electronic control panel prepared for wall mounting

EP VERSION:

- 1 Pressure transducer

- Emergency pressure switches (one for each pump)

- IEC-compliant pump control panel built and wired in metal case

IP VERSION:

- 1 Pressure transducer

- CEI-compliant inverter panel made and wired in metal case

PV VERSION:

- Pressure transducer (One for each pump)

- PumpVar on-board motor inverter (One for each pump)

AREAS OF APPLICATION

{INDUSTRIES

{INDUSTRIES

{AGRICULTURE

{AGRICULTURE

{RESIDENTIAL

{RESIDENTIAL