MAIN FEATURES

The use of centrifugal and self-priming pumps is vital for emergency response and civil protection in the management of emergencies and natural disasters.

Self-priming, in particular, allows operators to use transportable type pumps and always respond to the most pressing needs, since the suction pipe doesn't have to be filled.

In the event of floods, overflow and flooding, the use of centrifugal pumps allows civil protection operators to pump excess fluids in a timely manner, preventing the situation from degenerating.

If you work in urban or industrial contexts, you will have to deal with flooding of basements, foundations, basins and other submerged spaces that if they are not quickly freed from the water, can also cause serious damage to the building structures.

ADVANTAGES

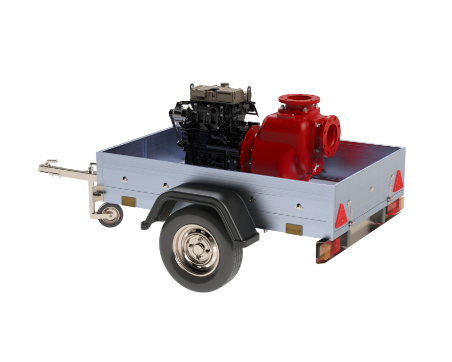

Rapid response: Firefighters and Civil Protection must also resolve serious situations caused by earthquakes. In these cases, the intervention time must be very short and it is difficult to predict in which contexts it will be necessary to operate.

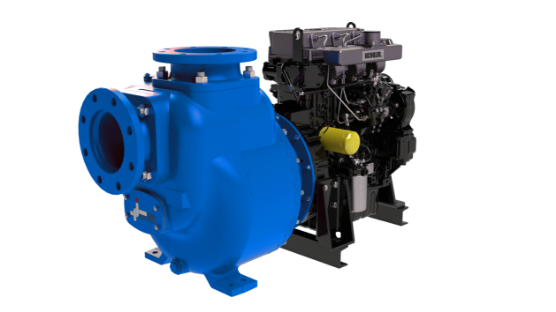

For this reason we have provided pumps for emergencies of various kinds: wheeled motor pumps, self-priming or vacuum-assisted electric pumps, to take make the utmost of the advantages and strengths of the various models and circumvent the limits that may arise on a case-by-case basis.

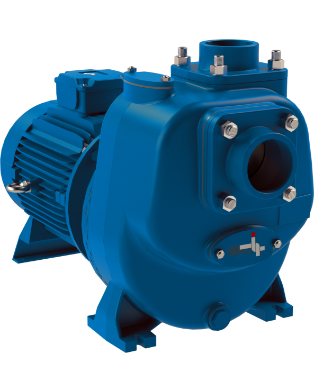

Self-priming centrifugal pumps of the W-WS series are used for the drainage of excavations, lowering of groundwater with wellpoint systems, handling of water and bentonite sludge, drainage of flooded areas.

The impeller used is able to convey water containing solid and liquid bodies with a high content of sand and gravel.

MANUFACTURING SPECIFICATIONS

- Pump body: Cast iron

- Motor support: Cast iron

- Impeller: open blade in cast iron

- Shaft: Stainless steel

- Non-return valve: clapet in Nitrile rubber/Steel

TECHNICAL SPECIFICATIONS

- Maximum temperature: liquid -15° C + 70° C,

- Ambient Temperature: +40° C,

- Maximum pressure: 6 bar

- Asynchronous 2-pole motor, C.I.F, IP55

The W-WS series self-priming centrifugal electric pumps, thanks to a specially shaped body, allow suction priming without the need to fill the pipe in advance and without the use of the foot valve.

During priming, the air is brought inside the pump by the vacuum created by the rotation of the impeller and mixed with the liquid contained in the body.

Once it has arrived in the priming chamber, the lighter air continues towards the delivery manifold of the pump, while the heavier liquid falls into the volute.

The atmospheric pressure then pushes the liquid to be sucked up to the impeller.

When the liquid reaches the impeller blades, the pump is primed. The pump can also operate with a liquid/air mix.

In the event of intake air entering, the liquid that remains in the pump body allows the subsequent automatic priming.

The non-return valve placed in suction prevents emptying of the suction tube, accelerating the restarts.

W-WS self-priming electric pumps are available with free shaft, with coupling via elastic coupling or in a flanged version with a normalised electric motor.